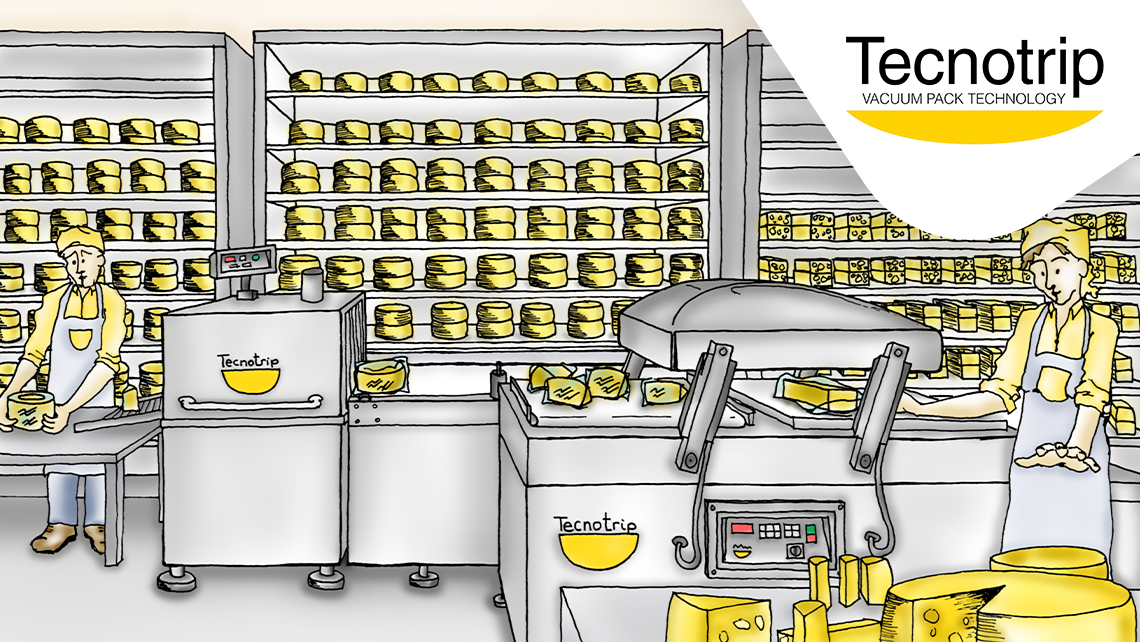

Compact, robust, agile to use, easy to clean, fast, complete, made with the best components

Optimized process times and careful treatment of products.

- Synchronized with shrink wrap tanks. Through a conveyor belt that transports the products from the packaging machine, if the situation requires it.

- The tank can be synchronized, at the same time with a bag dryer, for later labeling.

|

|

Main features

Types of welding:

- Simple welding

- Simple welding + excess cutting

- Individually adjustable double welding

- Bi-Active welding + individually adjustable excess cutting (model EVA9-11)

Versions:

- Different locations of welding bars (model EVA-9-11)

Pump: Bush

- EVA-9-11:250M3/h

- EVD-A-20: 250M3/h

- EVC-26/27:250M3/H (1 ó 2 pumps)

Digital programmer:

- 30 selectable programs

- Vacuum control by sensor

- Intelligent vacuum control

- Progressive vacuum function

- Gas inlet control by sensor

- Progressive air intake "Soft-Air"

- Vacuum verification program

- Manual vacuum stop• Test program

- Packaging cycle counter• Oil change control

- Preheating pump program

Main functions:

- Automatic ejection of the product, once the packaging cycle is finished

- Adjustment of the height of the conveyor belt of the chambers (models EVA-9-11 and EVD-A-20)

- Easy removal of conveyor belt for cleaning

- If synchronized with the conveyor belt and shrink tank; a cell located at the entrance of the tunnel, detects the passage of the packaged product and initiates the shrink wrapping cycle

|

|

EVC-26 y EVC-27: https://www.youtube.com/watch?v=PlNyI8gr7Mk&t=71s

EVD-A-20: https://youtu.be/G8Uhc5BIvag

EVA-9-11: https://www.youtube.com/watch?v=H_va9RLdBV8

EVC-A-30: https://www.youtube.com/watch?v=v5JzsKIKdrQ

Benefit from our Integral Service:

DO YOU WANT MORE INFORMATION?

ENTER OUR GENERAL CATALOG --> LINK

CONTACT US --> LINK

SOCIAL MEDIA --> INSTAGRAM / FACEBOOK / LINKEDIN