Packaging programmes

We are pioneers in the application of vacuum-packaging techniques.

Sealing

Seals bags/trays without vacuum.

Vacuum

Vacuums and seals bags/trays.

Vacuum and gas

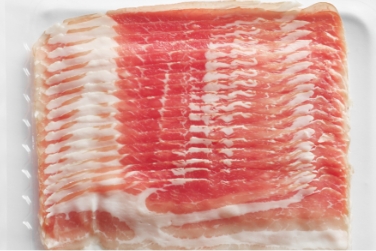

The use of a combination of vacuum with certain gas mixtures such as nitrogen (N2) or carbon dioxide (CO2) protects the packaging of fragile products, prevents deformation and maintains the colour of the meat.

Vacuum and skin

Thanks to the vacuum action, this system allows the film to adhere perfectly to food like a second skin. Ideal for value-added products that seek enhanced presentation.

Longer shelf life of vacuum-packed products

There are several factors that influence the shelf life of foodstuffs, including

the characteristics of the raw material, the composition and structure of the food,

freshness and cleanliness, as well as the manufacturing process.

The main factors that influence the shelf life of a product are:

- THE SPEED AND DEGREE OF DETERIORATION OF A FOODSTUFF

-

And, therefore, the reactions that take place in it during storage depend on many factors both inherent to the characteristics of the food and external factors.

- MOISTURE MIGRATION

-

It may significantly affect physical characteristics, especially in foods with low or high moisture content.

- PROLIFERATION OF MICROORGANISMS

-

Sensory or visual quality can deteriorate.

- TEMPERATURE

-

For example, freezing can lead to the formation of crystals, which can cause significant damage such as dehydration and textural changes, among others, in products such as fruit and vegetables or meat and fish. On the other hand, the increase in temperature can cause melting of fats, destabilisation of emulsions, etc. Furthermore, and in addition to the above, it generally speeds up chemical reactions, resulting in faster spoilage of the food.

- LIGHT

-

It accelerates the oxidation processes, which is particularly important in products with high fat content prone to rancidity or in foods with pigments susceptible to oxidation (mainly pigments).

Vacuum packaging prolongs the shelf life of the product, preserves its quality and properties (odour, colour), prevents it from drying out, protects it from external influences (light, humidity) and facilitates storage and transport.

If the food is free of oxygen, it is also free of the proliferation of microorganisms and aerobic bacteria.

The vacuum prevents or delays:

The growth of microorganisms.

The factor that most influences the growth of microorganisms, in addition to the intrinsic characteristics of the food, is the storage temperature and the gaseous composition inside the container. In this regard, the packaging material must guarantee either that there is no significant gas exchange between the inside of the container and the outside, or control the diffusion rate.

Lipid oxidation.

In foods where microbiological growth does not take place or is negligible, the main deteriorations are due to lipid oxidation, resulting in rancidity and the formation of off-flavours, as well as enzymatic and non-enzymatic browning, which makes the food go brown and alters the smell and taste. In both deteriorations, the main factors that influence the shelf life are oxygen and light. With these foodstuffs, it is very important that the material prevents, as in the previous case, the exchange of gases between the inside of the container and the outside – namely, the material must have a low permeability, mainly to oxygen. On the other hand, in products exposed to light, this can pose a significant risk. In this regard, for example, although the consumer usually prefers transparent materials as they can see the content, this can lead to a significant decrease in their shelf life.

Physical deterioration:

Another important type of deterioration is physical – such as loss of crispness in foods with low humidity or, in the opposite case, increased hardness. This type of deterioration is highly influenced by relative humidity, so in these cases, the material must have a low permeability to water vapour to prevent the migration of environmental humidity to the product or vice versa.

The type of packaging material

also influences the shelf life.

The type of packaging is a key factor in influencing the shelf life of the food. Its main function is to protect the food from extrinsic factors – humidity, light, temperature, oxygen and microorganisms – as well as from mechanical damage.

It is important to use good quality vacuum bags to ensure durability of the vacuum. In addition to protecting the food, it must comply with the technical requirements inherent to the process to which it is to be subjected. Its properties such as permeability to oxygen and water, mechanical properties and transparency.

Table showing the approximate shelf life of the different vacuum-packed products:

- PRODUCT IN FRIDGE

-

Producto en la nevera Sin envasar Envasado Carne fresca 2 días 6 días Carne cocida 4-5 días 8-10 días Embutidos 90 días 364 días Fruta fresca 3-7 días 8-20 días Hierbas frescas 2-3 días 7-14 días Queso

(en función de la clase)5-15 días 13 a 55 días Lechuga 3 días 6-8 días Pescado fresco 2 días 4-5 días Pollo 2 días 6 días Precocinados 2 días 10 días Vegetales frescos 5 días 18-20 días - PRODUCT IN FREEZER

-

Producto en el congelador Sin envasar Envasado Bollería 6-12 meses 18 meses Carne fresca 6 meses 18 meses Champiñones 8 meses 24 meses Fruta 6-10 meses 18-30 meses Hierbas frescas 6-10 meses 18-30 meses Pan 6-12 meses 18-36 meses Vegetales frescos 8 meses 24 meses - PRODUCT AT ROOM TEMPERATURE

-

Producto a temperatura ambiente Sin envasar Envasado Bollería 2-3 días 7-10 días Café y té 30-60 días 365 días Chips, snacks 5-10 días 20-30 días Frutos secos 30-60 días 120-180 días Galletas 120 días 300 días Pasta no cocida 180 días 365 días Pan 2-3 días 7-8 días

Sectors and products

GASTRONOMY

Kitchens

PACKAGING SOLUTIONS

Packaging machines

Heat sealing machines

CUTTING SOLUTIONS

Multi-cutters

PACKAGED PRODUCT

MEAT PROCESSING INDUSTRY

Workshops

Factories

Packing centres

PACKAGING SOLUTIONS

Packaging machines

Heat sealing machines

CUTTING SOLUTIONS

Multi-cutters

Chop cutters

PROCESSING SOLUTIONS

Shrink tanks

Vacuum drums

Vacuum kneader drums

Refrigerated vacuum kneader drums

Brine injectors

PACKAGED PRODUCT

FOOD PROCESSING INDUSTRY

Workshops

Factories

Packing centres

PACKAGING SOLUTIONS

Packaging machines

Heat sealing machines

CUTTING SOLUTIONS

Multi-cutters

Cutters for fruit and vegetables

PACKAGED PRODUCT

DISTRIBUTION SECTOR

Retail

Wholesale

Online

PACKAGING SOLUTIONS

Packaging machines

Heat sealing machines

CUTTING SOLUTIONS

Multi-cutters

PACKAGED PRODUCT

NON-FOOD INDUSTRY

Pharmaceutical factory

Factory industry

PACKAGING SOLUTIONS

PACKAGED PRODUCT

Gas mixture for vacuum packaging (MAP)

Some foods are delicate because of their shape and size, and need a vacuum bag that does not crush or deform them while preventing sticking and protecting against breakage.

The MAP (Modified Atmosphere Packaging) technique is used to package and preserve the most fragile foods using a mixture of gases.

This gas mixture is also called INERT GAS.

To pack with MAP or inert gas, just connect the gas cylinder to your machine (prepared accordingly). With the programme established for this purpose, the gas will be gradually injected into the container and then sealed.

You can use Modified Atmosphere Packaging for products such as pasta, pastries, vegetables, fruits, pre-cooked dishes, etc.

Different gases are often used in proportional mixtures. The most common are nitrogen and carbon dioxide, since they delay oxidation.

Oxygen is only recommended under very specific conditions, as it promotes food spoilage.

It is advisable to contact your trusted gas supplier.